What is an Air Handling Unit (AHU)?

An air handler or air handling unit (AHU) is a machine used to condition and circulate air as part of a heating, ventilating, and air-conditioning system.

It usually contains

- one or more fans,

- heating and or cooling heat exchangers,

- filter racks or chambers,

- sound attenuators and

- dampers.

Air handlers usually connect to a ductwork ventilation system that distributes the conditioned air through the building and returns it to the AHU. Water is delivered from the central plant to AHU, and is passed through a heat exchanger. This process is controlled by a DDC control loop which adjusts the water flow through the heat exchanger using a control valve, the valve is modulated by the DDC maintaining a desired temperature either in a space or leaving the AHU.

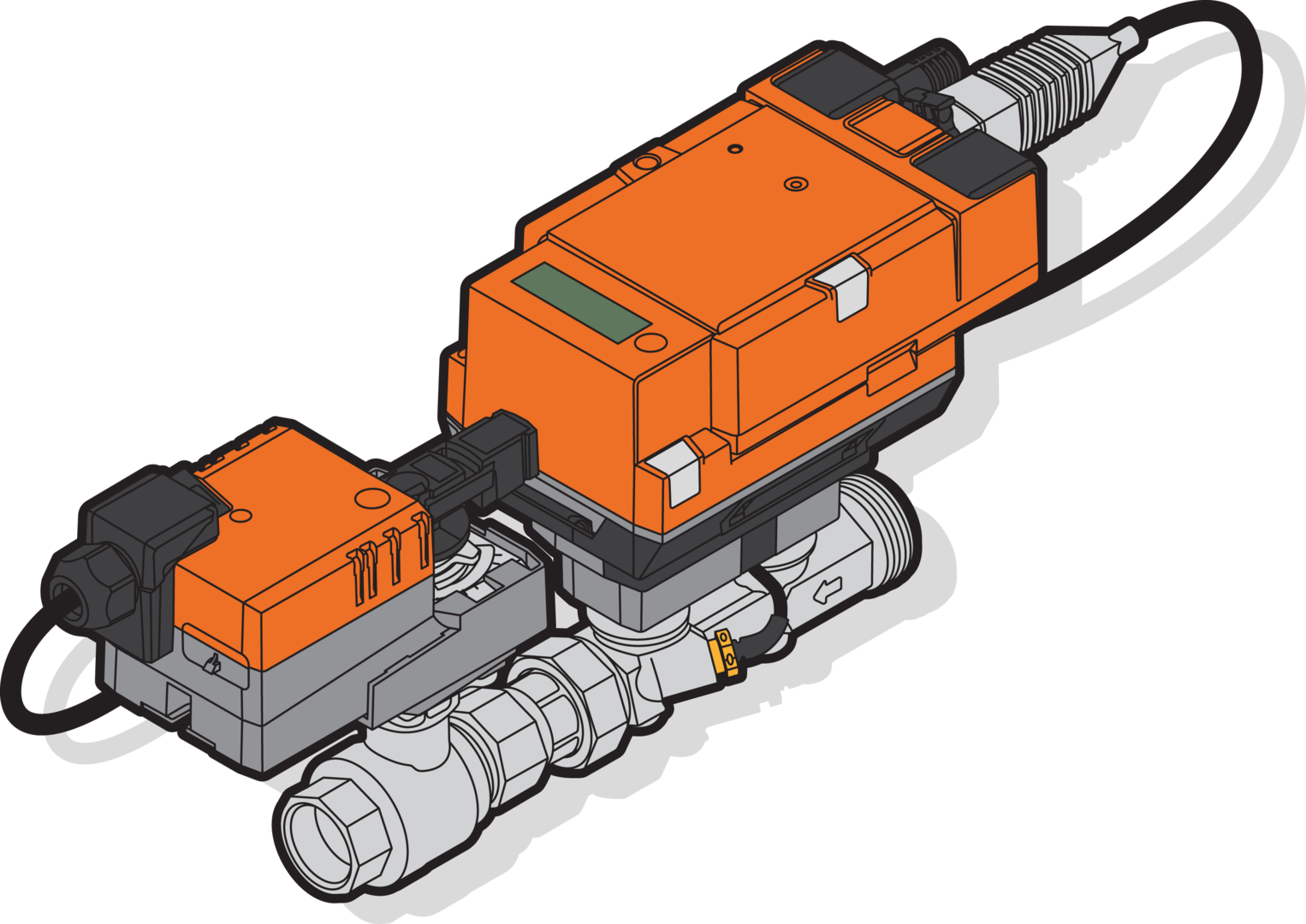

Order the new Belimo Energy Valve™ now

Learn how the Energy Valve improves your air handling unit

Common issues in AHU applications

Many AHUs in the field suffer from poor performance, principally for the following reasons:

Why you should choose the Belimo Energy Valve™ in an AHU application

If a heating or cooling system is operated with excess water flow, this cannot be converted into higher heating or cooling power. In this case, the temperature spread between supply and return decreases. The resulting low delta T syndrome is a clear indicator that the pumps are working harder than they need to, and central plant capacity is compromised.

Benefits of the Belimo Energy Valve™

Dynamic balancing by the Belimo Energy Valve™ ensures the correct amount of water at full and partial load.

- Reciprocal influence between valves is eliminated due to the dynamic balancing.

- Power control delivers identical heating or cooling output for any given input.

- The monitoring capabilities of the EV provides full system transparency (volumetric flow, temperatures, and cooling/ heating output) with data recording and optional archiving to the Belimo Cloud.

- Constant pump optimisation is possible using the physical valve position

Solving low delta T syndrome for better energy efficiency

Success Story: Belimo Energy Valve™ at Land O'Lakes, Inc., Minnesota

Belimo Energy Valve Plays Integral Role in Land O' Lakes, Inc.' s Corporate Facility Upgrade

Land O' Lakes, Inc.' s Corporate Sustainability Group began making plans to upgrade the facilities in order to increase efficiency and reduce energy consumption. HVAC systems were a particular area of focus due to the fact that as the buildings aged, they became more difficult to cool and meet desired discharge air temperature set points (especially in the summer months). Improving occupant comfort was also a priority.

After conducting a thorough review of piping, valves, and instrumentation, officials concluded that in order to solve the problem, various infrastructural improvements would have to be made. They then began the process of searching for a solution, which eventually led them to the Belimo Energy Valve™.